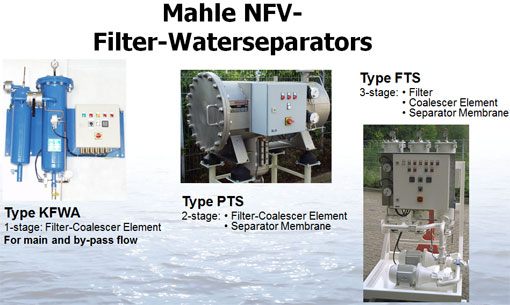

Fuel-Treatment Systems / Filter Water Separators

February 3, 2011 No CommentsFuel-Treatment Systems / Filter-Water-Separators of Mahle NFV

Diesel fuel oils

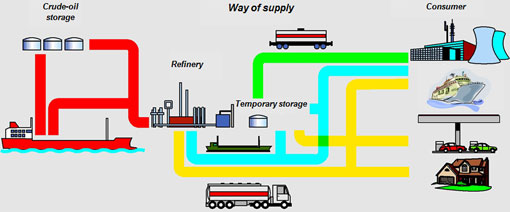

Dieseloils, e.g. medium distillates like HEL, MDO, MGO, F75 / F76, F54 etc., are industrial manufactured products with specific defaults but enormous differences.

Especially the way from the refinery to the road tanker, bulkcarrier or pipelines in the tank reservoirs and from there through further carriers to the end-user is causing unintended and not calculable changement of the fluids.

Contaminations

The contaminations caused by the previously mentioned ways are:

Solids:

- particles of rust in different sizes

- dust and sand

- sediments of the products

Water, leading to:

- micro organisms

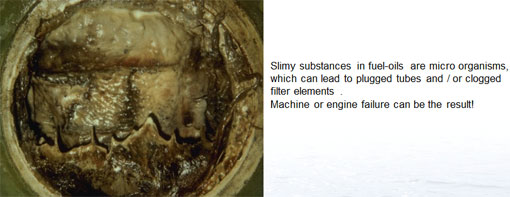

An effective fuel-treatment means suitable filtration with simultaneous water-separation.

SOLID

Filtrationtest with a contaminated fueloil MGO, stored in an aluminium tank.

In the range of 1,2 µm only parts of oxydations remain.

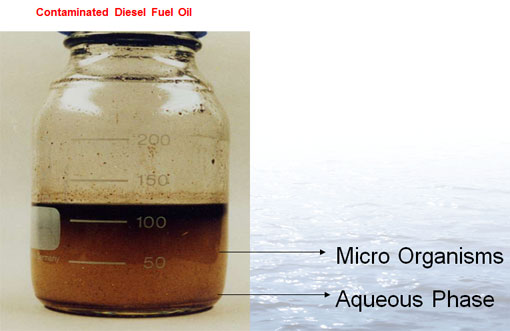

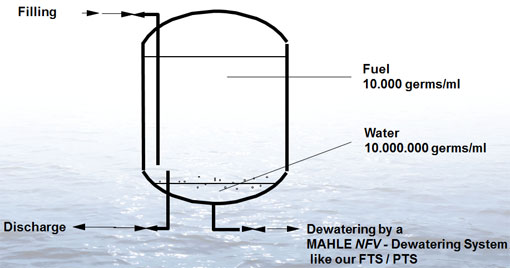

WATER/MICRO ORGANISMS

Reason for contamination with water:

Normally water in diesel fuel oils occures out of:

Diesel fuel oil with a temperature of 20°C is already binding 70 ppm water, without causing a dull. Technical delivery conditions permit even a much higher water – content.

Max. permissible water-contents under technical delivery-conditions:

Removing water out of medium-distillates down to a minimum possible rate has the following reasons:

the limit for micro organisms growing is up to

ca. 50 – 60 ppm non-solved water

In this tank(Al Mg Si 4,5) the silicons served as trace minerals and hence as fertile soil for micro organisms.

A black slimy „placenta“ with a particle-size of approx. 1µm grew.

The solution is: Fuel-Treatment with a MAHLE NFV – Dewatering System

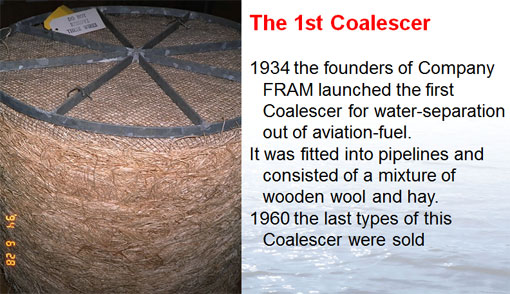

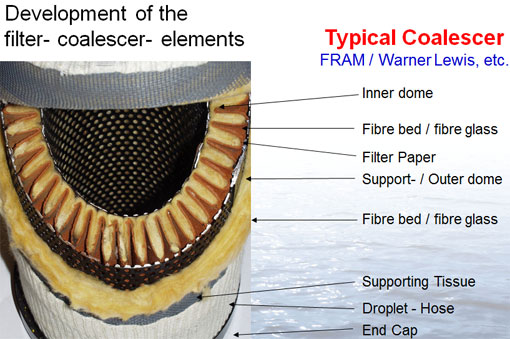

Development of the filter- coalescer- elements

The classic Coalescer initially had been developed for the whole aviation-range, i.e. normally for a clean and low-viscosity product of low density.

Sorry, the comment form is closed at this time.